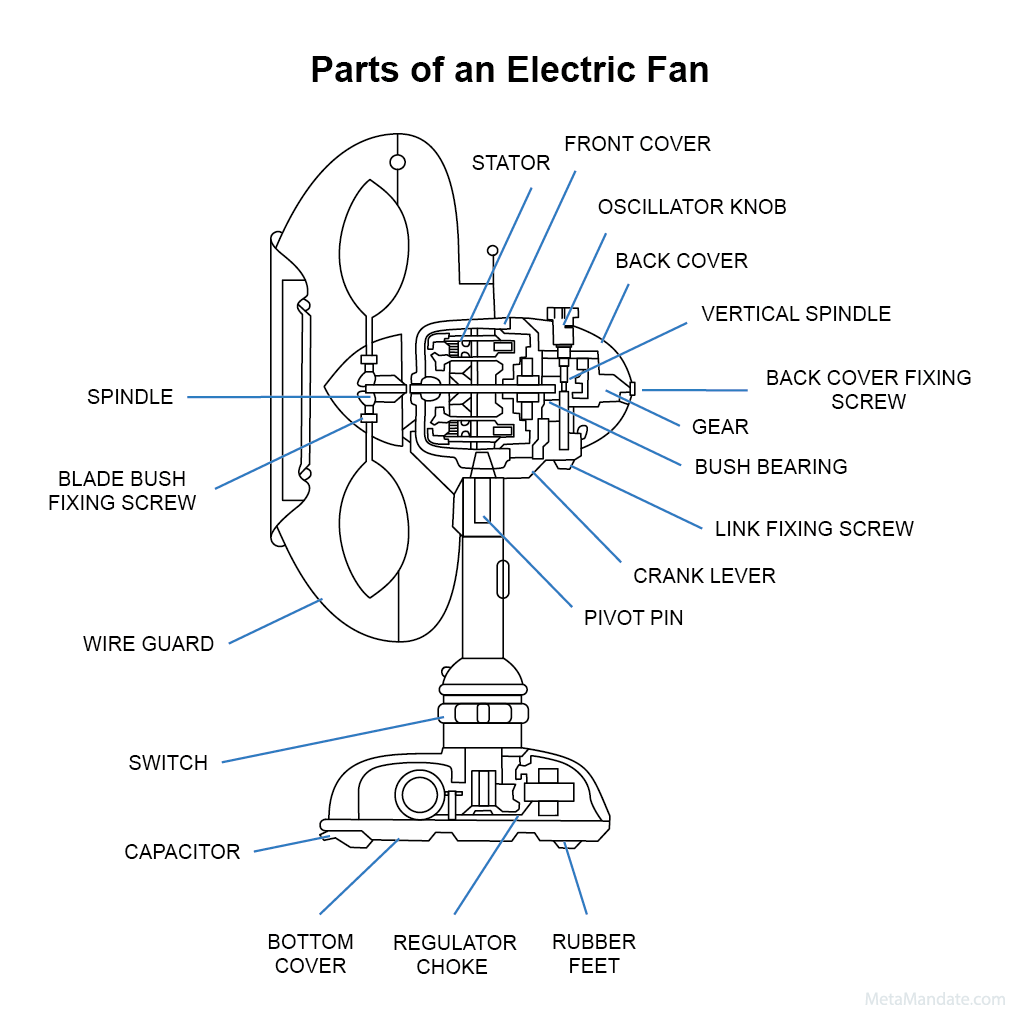

Here are the 23 parts of an electric fan:

- Rubber feet

- Regulator choke

- Capacitor

- Blade bush fixing screw

- Spindle

- Front cover

- Stator

- Oscillator knob

- Back cover

- Vertical spindle

- Gearbox

- Back cover fixing screw

- Bush bearing

- Link fixing screw

- Switch

- Pivot pin

- Crank lever

- Wire guard

- Bottom cover

- Fan blades

- Power cord

- Electric wiring

- Fan motor

So if you want to learn all about the parts of an electric fan, their names, and their functions, then this article is for you.

Keep reading!

Table of Contents

- #1 Rubber Feet

- #2 Regulator Choke

- #3 Capacitor

- #4 Blade Bush Fixing Screw

- #5 Spindle

- #6 Front Cover

- #7 Stator

- #8 Oscillator Knob

- #9 Back Cover

- #10 Vertical Spindle

- #11 Gearbox

- #12 Back Cover Fixing Screw

- #13 Bush Bearing

- #14 Link Fixing Screw

- #15 Switch

- #16 Pivot Pin

- #17 Crank Lever

- #18 Wire Guard

- #19 Bottom Cover

- #20 Fan Blades

- #21 Power Cord

- #22 Electric Wiring

- #23 Fan Motor

#1 Rubber Feet

Rubber feet are located at the fan base. Turning on your electric fan, you wouldn’t want it to budge around from the increased motion. The rubber feet help keep the electric fan in place.

More common in table fans, they also assist in absorbing surface vibration while it’s on.

#2 Regulator Choke

The frequency coming in from your energy input might be too much. The choke in the electric fan helps in regulating the high frequencies coming in to avoid any disconnection from the electrical grid.

There are other types of regulators you can find for your fan. There are resistance wire or electronic types available.

#3 Capacitor

If you’re wondering what’s responsible for a fan’s spin, you should look into its capacitor. It functions through a magnetic flux charge, otherwise known as, torque, to keep the fan in motion.

An electric fan’s capacitor is likely divided into several phases to create the magnetic flux. This makes the fan spin towards the produced magnetic field.

#4 Blade Bush Fixing Screw

This screw is an integral part of the electric fan’s rotational motion. It secures the fan’s blades. It’s lined with metal and acts as the axis of the blade’s spinning mechanism.

#5 Spindle

You can easily find this part in the middle of any electric fan. It acts as a rotating connector for all the fan’s blades. It’s the main arbor of the fan.

The spindle moves in a parallel direction to the fan’s blades.

#6 Front Cover

This cover guards any electric fan’s frontal head region. This part houses the electric fan’s vertical spindle, stator, and other rotary gear.

#7 Stator

The stator part gives off a magnetic field. This powers the electric fan’s spinning armature, which is coil-shaped and electrically induced.

The armature is responsible for sending electronic conduction throughout the field to power the fan’s torque.

#8 Oscillator Knob

One of the most integral features of an electric fan is its movement. You want a fan that can rotate back and forth to get more coverage.

The oscillator knob, as its name suggests, aids in the fan’s oscillating movements. It’s located behind the fan’s head.

In addition, you’ll notice that the knob extends from the fan’s cover. Pulling it upward activates its oscillating mode while pushing it down keeps it in place.

#9 Back Cover

The back cover of the electric fan protects all of its internal parts located in the head. This includes the gearbox, oscillator knob, electric wires, and copper windings.

#10 Vertical Spindle

You can find this spindle part near the electric fan’s oscillator knob. Instead of moving in a parallel direction to the blades like the main spindle, the vertical spindle moves perpendicularly along with the oscillating motion of the fan.

#11 Gearbox

This is your electric fan’s main unit, located at its head. It mostly consists of mechanical hardware. Most, if not all, electric fans come with three speed options: low, medium, and high.

The gearbox controls the energy output. It also transitions the output to either reduce the speed or increase the torque.

#12 Back Cover Fixing Screw

In the back of the fan head where the oscillating rod is held, there’s a back cover fixing screw. This screw bolts together the back casing of the fan with the rotary gear.

#13 Bush Bearing

Since an electric fan is filled with numerous rotating gear, you might encounter the issue of too much friction. This is where the bush bearing comes in.

It’s created to make a bearing surface for the mechanical parts. The internal bearing is coated in an oil film or made with plastic to provide the ideal working space for the electric fan’s internal parts.

#14 Link Fixing Screw

This part fastens the oscillating knob and holds things together as the fan maintains a steady swaying flow. You can find the link fixing screw near the bottom of the head, right below the oscillating knob.

#15 Switch

With a flip of the switch, your fan is on. Simple right? Well, the mechanics involved inside might be a bit more complicated.

The power switch, when activated, immediately draws outside electrical current from your cord and into the fan’s motor. While the journey may seem long, it’s all done in a blink of an eye.

#16 Pivot Pin

This pin holds the fan together as it oscillates. It functions as the axis of the electric fan, pivoting it in place as it rotates.

#17 Crank Lever

The crank lever mechanism mainly assists in transferring the rotary motion in an electric fan, to a reciprocating one. This allows the fan to oscillate more easily.

#18 Wire Guard

Leaving the fan bare-bladed is a disaster waiting to happen. The wire guard protects you and everything near the fan from the dangerously fast-moving blades.

It’s especially important if you have any curious children or pets roaming around the house. If safety is a main concern, we recommend considering fans with narrow-holed wire guards. It decreases the risk of accidents and injuries.

#19 Bottom Cover

This part of an electric fan essentially provides bottom protection for the fan’s base. It covers all of the fan’s crucial motor parts and provides a surface for the rubber feet to stick to as well.

#20 Fan Blades

You can’t have a fan without blades. Otherwise, you’d just be carrying a spinning motor.

Fan blades can come in a variety of numbers such as three, four, or more. You can also choose from a plethora of blade designs to suit any style.

Blades can be composed of plastic or aluminum. They are mounted to the electric fan’s spindle. Their speed can reach up to 400 revolutions per minute (RPM).

#21 Power Cord

You use this cord to connect it to your house’s electrical supply. Make sure to balance the frequencies. If it’s less or more than your energy output, it can cause an imbalance and result in overheating.

#22 Electric Wiring

You can think of the wiring as the messengers of electric current. They send the electric signals to the fan’s motors, which triggers the blades to move.

#23 Fan Motor

Consider this part the beating heart of any electric fan. It dispenses the input energy and controls its output.

The motor is a larger part of the fan and contains several parts, including the electric wiring, stator, and rotors. Fan motors have not only served their function in table fans, but have also evolved the entire mechanical industry.

They’re mainly used for ventilation purposes. You can also find fan motors in a variety of devices, such as hair dryers, computers, and microwaves.